When more of your engineers resolve more issues, first time, call out costs are reduced and business downtime is minimised. As a result, customers are happier, companies run more efficiently and are more profitable. Sounds easy. How do you make it happen?

What is a first time fix rate (FTFR)?

First time fix rate (FTFR) is defined as the percentage of times an engineer is able to fix an issue on their first visit to a site following a callout.

Why is FTFR so important?

Put simply, the higher the FTF percentage is, the better your engineers or contractors are performing.

If an engineer solves a problem without having to make an additional visit with extra support, information, or parts - it minimises disruption to the business and saves everyone time and money.

On the other hand, if engineers are unprepared, fixes are ineffective and return visits are necessary, customers get frustrated and costs escalate.

What’s a good first-time fix rate?

According to numerous FM studies high-performing companies regularly record first time fix rates in excess of 90%. In fact, the classic Aberdeen Group study into FTFRs drew a strong parallel between commercial success and first time fix rate.

"Businesses with the best overall commercial performance resolve 98% of their engineering problems in a single call out."

Source: Aberdeen Group

What causes a poor first time fix rate?

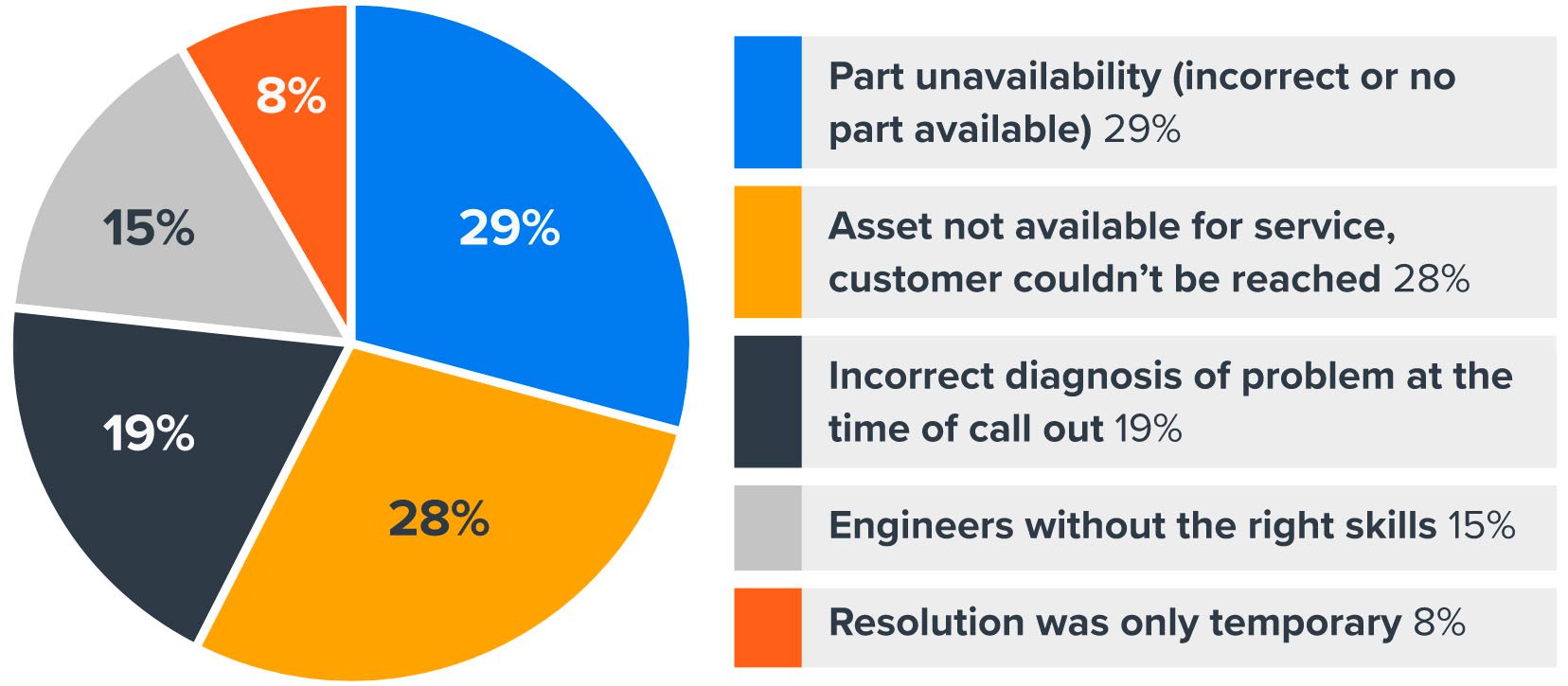

The Aberdeen Group study broke down the causes of low FTFRs as follows:

Obviously, First Time Fix rates will vary depending on the type of business you’re operating and the complexity of your engineering challenges. But poorly performing businesses typically see FTFRs of less than 70%.

Lack of communication is the common factor

But the good news is, improving the speed and accuracy of your asset management is within reach for most businesses.

92% of the time, it seems, a low first time rate is down to poor communication rather than anything else. Either the right engineer has not been sent, the correct information has not been given to them, or they weren’t able to gain access to the site in the first place.

All these problems can be addressed with a better set of communication tools driven from a central data hub.

“Invest in mobile tools to enable faster answers and real time time insights for the field team”

Source: Aberdeen Group

10 ways to increase your FTFR

1. Send the right people

Pretty obvious, but an easy mistake to make. If you don’t send the right technician to the job, they’ll not be able to fix the problem. When a work request comes into your helpdesk, can you instantly determine the discipline(s) required? Can you easily select an engineer who’s best suited to carry out that work e.g. by location, skills and experience? Without digital tools to help you triage and automate work requests it’s not easy to match suitable and available engineers to jobs as they come in.

2. Give engineers the right information

Turning up without the right part or tool is a major problem for your FTFR. Maybe the exact nature of the job hasn’t been described properly in the work request. Maybe the engineer just couldn’t tell what tools or parts they’d need from the information given. The more information that can be contained in a work order, including asset information, photos and videos, the better. Access to the complete service history of the asset will also help engineers prepare for the job, identify common failures and cut down on the need for return visits.

With our CAFM engineers have a clear communication pathway to accelerate fixes. They can message with site managers, get photos and ensure they have all the information they need before they go on site.

Joe McCann - Facilities & Project Support Manager, TeamSport

3. Keep teams communicating

Engineers often need to clarify what’s required of them. They need to be able to ask questions about the job before they get there and report back to HQ if there’s a problem. A three way conversation between end user, helpdesk and engineer in a single stream (rather than spread across different communication platforms) will cut down on misunderstandings and keep everyone on the same page.

4. Keep customers notified

If a third of call outs end in a repeat visit because the customer can’t be reached to give the engineer access to the asset - this points to a massive communication problem. FMs need the digital tools that can notify and remind customers when an engineer will arrive to fix their problem and inform them if they’re late.

5. Organise time efficiently

Engineer scheduling can directly impact your FTFR, if the order of jobs and the distance between them aren’t effectively managed, engineers can easily run out of time and have to come back at a later date to complete a job. Organising engineer diaries just using Excel or Outlook is a complex task. It’s practically impossible to do efficiently without integrated digital tools.

The right CAFM tool can help you with route optimisation in exactly this way, ensuring your engineers' days are organised in the most logical and efficient way.

6. Make sure your engineers are playing ball

Contractors and engineers need the tools to easily log their time, to record when and why they’ve had to leave a job unfinished. If they’re not doing this - you’re not going to have accurate data to analyse.

The big goal for us was getting contractors on board, so we could monitor their activities and control our spending with them. With our new CAFM, contractors are now using the system to record their time and manage their site visits. We have got excellent feedback from them, and we continue to listen and speak to them every day.

Ben Downer - Hard Services Manager, Co-Operative Bank

7. Gain visibility through data

FTFR data is vital business intelligence. Where it’s available in charts and tables, broken down by engineer and site, you’ll be able to quickly spot trends and take steps to solve problems.

The data should show you:

- Which engineers are performing the best and worst

- Compare engineers against each other and SLAs

- If particular locations or buildings have recurring asset problems

8. Use data to optimise performance

A poor FTFR can indicate real problems with specific engineer performance that are impacting organisational goals - or it can suggest that engineers just aren’t being well enough prepared for jobs and you need to improve your admin and communication.

At the same time, localised low FTFR and high numbers of recalls can suggest assets are coming to the end of their working lives or in need of more complete overhauls.

When you have visibility of this asset data you can make the changes that will make a commercial difference. You can begin to streamline your supply chain. You can direct more work to high performance contractors and have the oversight to make the strategic decisions that will improve your KPIs and meet SLA requirements more effectively.

Of course, when you have the data at your fingertips all this is straightforward, but most FMs don’t.

After we implemented our CAFM, we could begin to analyse supplier performance in more detail. We could see when ETA's had been changed. We could see when SLA's had been breached and act to improve our asset KPIs.

Joe McCann, Facilities & Project Support Manager, Team Sport

9. Choose a CAFM

Busy FM teams without centralised digital tools, working across multiple sites with multiple contractors face particular problems gathering data and working with teams to deliver better FTFRs.

Those using multiple platforms, email, mobile and spreadsheets to manage engineers often find it impossible to capture the right data to track first time fix rates, let alone keep it up to date. But those using dedicated FM software for work order management often don’t perform better.

So much contractor management software is clunky and difficult to operate that it’s often ignored or abandoned by teams asked to adopt it. FMs who need to persuade contractors and engineers to use the solution and track their own performance often face an uphill struggle when the tools themselves are so difficult to use (and particularly when they’re not mobile optimised.)

"82% of high performing companies have a single repository of service history and facilities data such as a CAFM".

Source: Aberdeen Group

10. Choose a CAFM wisely

The right CAFM system can help you start rapidly improving your FTF rate.

But it’s all about choosing a user experience that makes it simple to capture, understand AND optimise the FTFR in real time.

How can you use FTFR in the future?

FTFR is, for many organisations, the ultimate key performance indicator (KPI), it’s an indispensable index of:

- Levels of customer satisfaction

- Levels of engineer competence/efficiency

- Where time and money is being wasted

- Where there are problems with assets/performance to investigate

FTFR can form part of internal and external SLAs that reflect the priorities of companies and enable them to manage customer satisfaction levels and reward team performance more effectively. An agreed FTFR level in a SLA can form the basis of fines and other sanctions imposed on FM teams. It can help you develop a system of continuous improvement that will help you optimise performance against your targets.

Improving you FTFR - here’s a CAFM checklist

Digital transformation of your asset management process to improve first-time fix rates and other KPIs doesn't have to be hugely expensive or disruptive for your organisation.

Great asset management begins at the level of people management, ensuring that the data and information everyone needs to expedite a work order is available when and where they need it.

So, if you’re choosing a CAFM - make sure you ask these questions to ensure teams are fixing problems, first time every time:

- Is it easy for end users to log issues in your system - does it streamline data capture?

- Can users add information to work requests e.g. upload photos and video via mobile?

- Is the system automated to reduce user error and improve flow?

- Can teams communicate easily through one portal - so no detail is missed?

- Are users notified when engineers are ‘on their way’?

- Does the contractor portal make it easy for engineers to log their time?

- Can the captured FTFR data be viewed and analysed easily by FMs?

- Can FMs make supplier decisions on the fly based on that data?

.png?width=680&height=700&name=Ai%20page%20module%20(2).png)