Asset tagging is the process of applying labels or tags to your company’s equipment and furniture, allowing for more effective inventory management. But what kind of tagging is right for your asset management process?

What is the best way to tag assets?

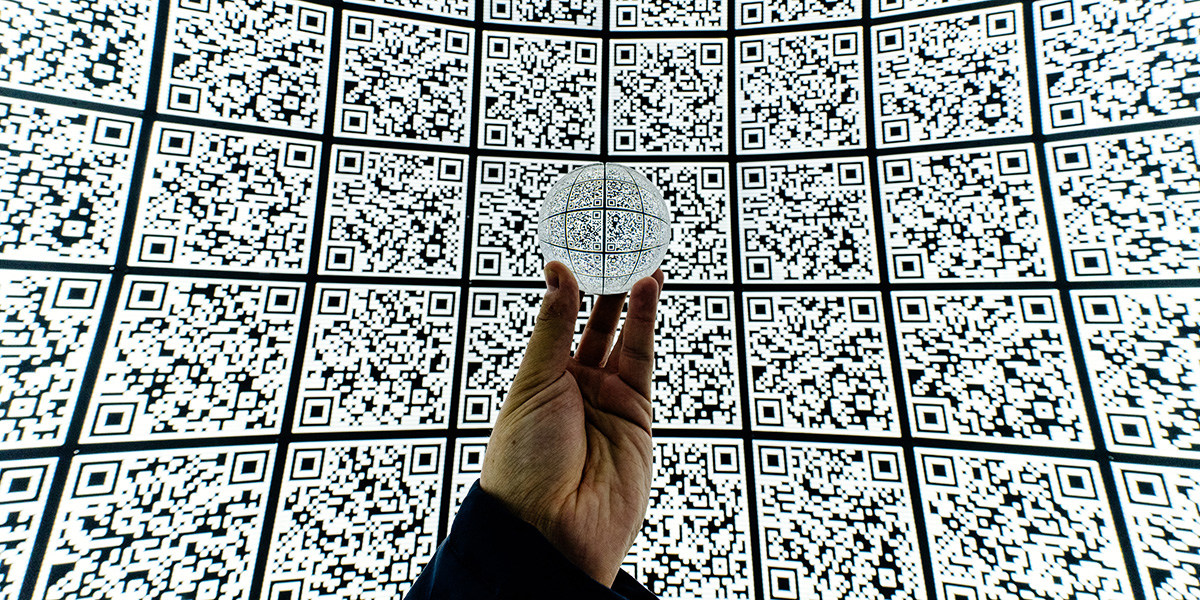

Fixed asset tagging has evolved rapidly in the last few years. Once it meant applying sticky labels to equipment printed with unique ID numbers referring to physical asset registers. But scannable codes and digital registers are now the chosen solution for most businesses.

QR, NFC, RFID asset tags are now being applied to all kinds of furniture and equipment, linking in real time to all the asset information FMs and contractors need to track their history and maintain them effectively.

Some businesses are even using the most sophisticated GPS asset tags to monitor the exact physical location of assets in real time.

What are the different types of asset tag?

- Bar code/QR codes

- NFC tags

- RFID tags

- GPS trackers

Each method of tagging has various pros and cons. For example, different kinds of barcodes have different levels of ‘scannability’ and can require different hardware and software to scan effectively. Meanwhile RFID, NFC and GPS tags can bring more functionality to your asset tracking, but add more expense and complexity to your tagging process.

The benefits of asset tagging

In general the key benefits you can expect from asset tagging with any kind of barcode or digital tag are around the streamlining of your maintenance, auditing and equipment tracking processes. With just one scan (or touch of a code/tag) engineers, contractors, auditors and, even equipment users themselves can:

- Create work requests for the asset

- Locate, access and update work orders relating to the asset

- Update asset property data such as Status, Condition, Location - particularly useful when performing audits

- Instantly retrieve details that will speed up maintenance tasks and decision making:

- View asset service history,

- View asset depreciation,

- View warranty information,

- View asset purchase costs, installation costs and total spend to date.

What are the pros and cons of different tagging solutions

QR codes

Unique QR codes can be generated easily and quickly within CAFM systems ready for printing and applying to your assets. Once printed on labels and stuck to your asset you can easily scan them with mobile devices to gain access to their service history and other details.

You will have to consider where these stickers are placed on devices to ensure they remain intact and scannable, but they are remarkably resilient - only 30% of a QR code needs to be intact for a scan to be successful.

QR codes associated with specific equipment can open specific web pages and apps, updating systems about the current location of an asset (based on the phone’s location) and details of who last had sight of it.

NFC tags

NFC (Near field communication) chips are unpowered devices containing digital information that are small enough to be embedded in stickers and affixed to devices. As the name suggests, the tag can only work when in close proximity to the scanning device.

When a mobile phone with NFC capabilities touches the tag, the chip is powered up and the data stored in the chip is transferred to the device. In a typical asset tagging scenario this usually means opening a URL that links the user to asset records within an asset tracking system.

NFC tags are small and robust enough to be easily affixed to most kind of assets.

Unlike QR codes they don’t require line of sight or a particular level of light to be scanned effectively.

But, the NFC tag needs to be configured with the correct data to work and give the scanner the right information.

Unlike a QR code they can’t be generated and ‘printed at will’ so it’s generally a more costly and time consuming asset management solution to implement.

Active RFID (Radio Frequency Identification) tags

While QR codes and NFC tags are passive containers of information, RFID’s active capabilities and longer transmission range mean they can be used in different ways in asset tracking systems.

An RFID tag affixed to an asset can be read by fixed scanners installed on doorways and other key points (or by staff using mobile phones or tablets).

Every time a tag is read it can automatically update asset tracking software to tell the business when it has been taken from a location and when it has been returned.

Active RFID tags have built-in batteries allowing them to transmit the data stored on to it directly to the reader. Even though their batteries do have a limited lifetime, they still last for years. The RFID tags have to be programmed, which requires specific hardware and software. It takes considerable configuration to make them work effectively.

GPS trackers

GPS trackers can be affixed to high value equipment transmitting real time information about the location of assets direct to asset management systems. This mitigates asset theft and ensures you can account for everything under your control.

With sophisticated GPS asset tracking software you can see an asset’s current locations overlaid on maps.

GPS tags can allow for geo-fencing, so that if an asset leaves a specific location, you’ll get an alert.

GPS can be small and highly robust (although more bulky than other ‘sticker’ solutions) and come with long-life battery solutions exceeding 10 years and more.

Right now, GPS is a very expensive solution and so it is typically only used for high value assets. But as technology advances and costs fall they could have much wider application in tracking all kinds of moveable assets across a wider range of businesses.

How much technology do you need?

CAFM suppliers offer businesses a range of asset tagging and tracking options for use as part of their solutions, with different kinds of hardware/software and investment required to make them work.

GPS tracking and RFID tagging of equipment can add layers of control and visibility to monitor individual asset movement, but can also add layers of complexity, time and expense to CAFM set ups. In the end, this complexity can stop businesses in their tracks as they try to get a grip on asset management.

How to get started with asset tagging

- Make sure your asset tagging process is as simple as possible to administer.

- Look for an asset tracking system that can generate unique codes (including QR codes) in the app itself.

- Choose a solution that doesn't require specialist programming tools or scanning hardware to set up and administer.

- Use durable and tamper-proof tags. Select tags made from durable materials that can withstand the environmental conditions of your facilities, such as heat, moisture, and physical wear.

- Train staff on tagging and tracking procedures - make this part of your onboarding routine.

- Agree clear and consistent tagging locations for each type of asset.

- Conduct regular audits (scanning tagged assets in property walk throughs) to ensure you have no ghost or zombie assets in your system.

Conclusion

Tagging is vital for tracking the asset location and condition of the equipment you own. It's key to making sure you've got visibility of asset utilisation and the compliance status of equipment in your real estate. But it doesn't need to be complicated or tech-heavy to work.

In the end, the success of your tagging initiative will depend on the clarity of your process and the quality of the asset management software you use.

Editor’s note: this post was originally published in 2021, and republished in June 2024 for accuracy.

.png?width=680&height=700&name=Ai%20page%20module%20(2).png)

%20(Landscape)).png?width=4375&height=625&name=THE%20FM%20FIX%20(Medium%20Banner%20(US)%20(Landscape)).png)